Papers on walking beam furnace

The are my publications in relation to the walking beam furnace

- On control structure design for a walking beam furnaceHedyeh Jafari, Miguel Castaño Arranz, Thomas Gustafsson, and 1 more authorIn 25th Mediterranean Conference on Control and Automation (MED) 2017

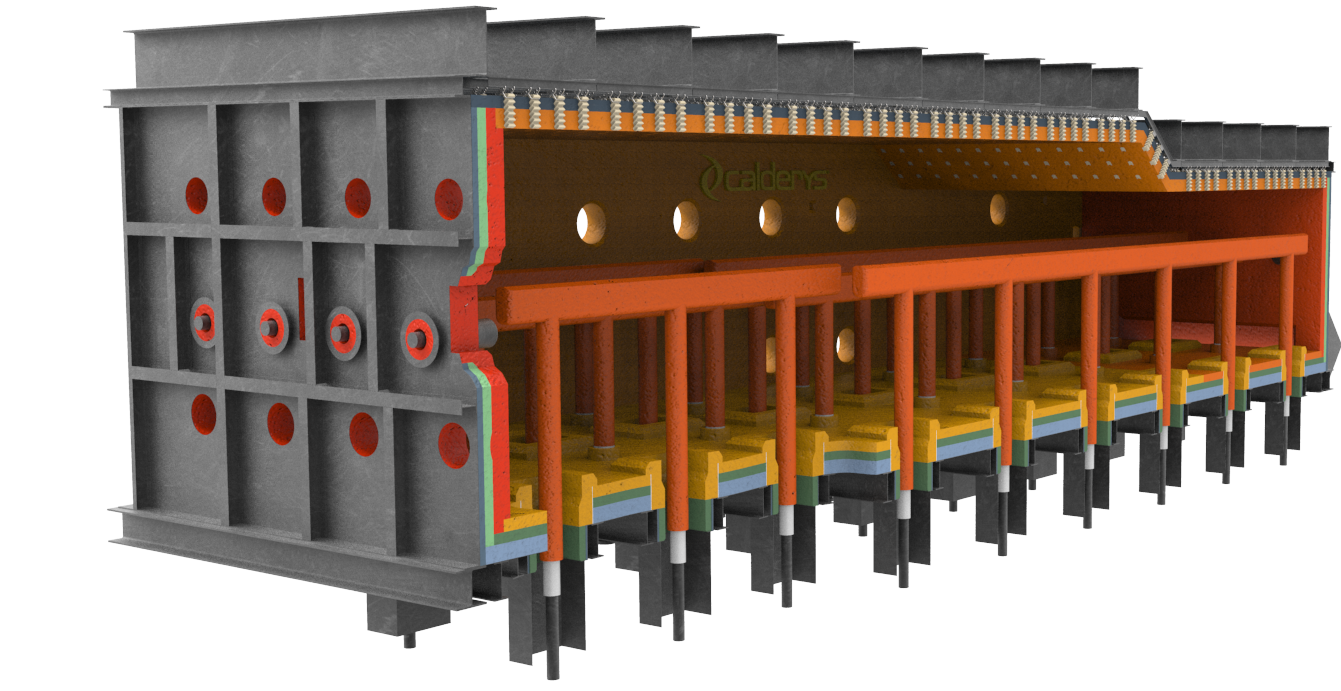

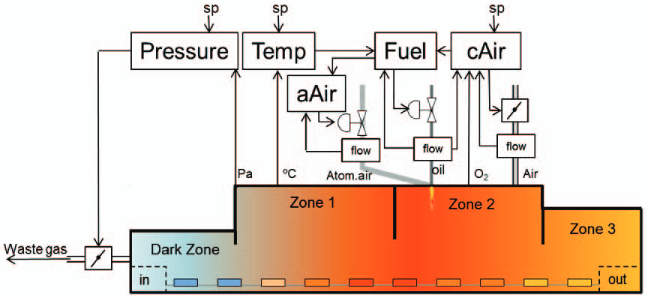

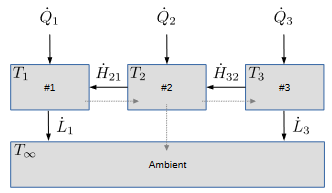

The aim of this article is to introduce a novel sparse controller design for the temperature control of an experimental walking beam furnace in steel industry. Adequate tracking of temperature references is essential for the quality of the heated slabs. However, the design of the temperature control is hindered by the multivariable (non-square) dynamic behavior of the furnace. These dynamics include significant loop interactions and time delays. Furthermore, a novel datadriven model, based on real life experimental data that relies on a subspace state representation in a closed loop approach is introduced. In the sequel, the derived model is utilized to investigate the controller’s structure. By applying the relative gain array approach a decentralized feedback controller is designed. However, in spite of the optimal and sparse design of the controller, there exists interaction between loops. By analyzing the interaction between the inputs-outputs with the σ 2 Gramian-based interaction methodology, a decoupled multi-variable controller is implied. The simulation result, based on the experimental modeling of the furnace, shows that the controller can successfully decrease the interaction between the loops and track the reference temperature set-points.

@inproceedings{jafari2017control, title = {On control structure design for a walking beam furnace}, author = {Jafari, Hedyeh and Casta{\~n}o Arranz, Miguel and Gustafsson, Thomas and Nikolakopoulos, George}, booktitle = {25th Mediterranean Conference on Control and Automation (MED)}, pages = {1355--1360}, year = {2017}, organization = {IEEE} }

- Cloud computing for big data analytics in the Process Control IndustryE Goldin, D Feldman, Georgios Georgoulas, and 2 more authorsIn 25th Mediterranean Conference on Control and Automation (MED) 2017

The aim of this article is to present an example of a novel cloud computing infrastructure for big data analytics in the Process Control Industry. Latest innovations in the field of Process Analyzer Techniques (PAT), big data and wireless technologies have created a new environment in which almost all stages of the industrial process can be recorded and utilized, not only for safety, but also for real time optimization. Based on analysis of historical sensor data, machine learning based optimization models can be developed and deployed in real time closed control loops. However, still the local implementation of those systems requires a huge investment in hardware and software, as a direct result of the big data nature of sensors data being recorded continuously. The current technological advancements in cloud computing for big data processing, open new opportunities for the industry, while acting as an enabler for a significant reduction in costs, making the technology available to plants of all sizes. The main contribution of this article stems from the presentation for a fist time ever of a pilot cloud based architecture for the application of a data driven modeling and optimal control configuration for the field of Process Control. As it will be presented, these developments have been carried in close relationship with the process industry and pave a way for a generalized application of the cloud based approaches, towards the future of Industry 4.0.

@inproceedings{goldin2017cloud, title = {Cloud computing for big data analytics in the Process Control Industry}, author = {Goldin, E and Feldman, D and Georgoulas, Georgios and Castaño, Miguel and Nikolakopoulos, George}, booktitle = {25th Mediterranean Conference on Control and Automation (MED)}, pages = {1373-1378}, year = {2017}, organization = {IEEE}, }

- Data-driven modelling, learning and stochastic predictive control for the steel industryDomagoj Herceg, George Georgoulas, Pantelis Sopasakis, and 5 more authorsIn 2017 25th Mediterranean Conference on Control and Automation (MED) 2017

The steel industry involves energy-intensive processes such as combustion processes whose accurate modelling via first principles is both challenging and unlikely to lead to accurate models let alone cast time-varying dynamics and describe the inevitable wear and tear. In this paper we address the main objective which is the reduction of energy consumption and emissions along with the enhancement of the autonomy of the controlled process by online modelling and uncertainty-aware predictive control. We propose a risk-sensitive model selection procedure which makes use of the modern theory of risk measures and obtain dynamical models using process data from our experimental setting: a walking beam furnace at Swerea MEFOS. We use a scenario-based model predictive controller to track given temperature references at the three heating zones of the furnace and we train a classifier which predicts possible drops in the excess of Oxygen in each heating zone below acceptable levels. This information is then used to recalibrate the controller in order to maintain a high quality of combustion, therefore, higher thermal efficiency and lower emissions

@inproceedings{herceg2017data, title = {Data-driven modelling, learning and stochastic predictive control for the steel industry}, author = {Herceg, Domagoj and Georgoulas, George and Sopasakis, Pantelis and Casta{\~n}o, Miguel and Patrinos, Panagiotis and Bemporad, Alberto and Niemi, Jan and Nikolakopoulos, George}, booktitle = {2017 25th Mediterranean Conference on Control and Automation (MED)}, pages = {1361--1366}, year = {2017}, organization = {IEEE} }